high quality metal lined slurry pump factories

Latest articles

Especially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

high quality metal lined slurry pump factories...

high quality metal lined slurry pump factories 【high quality metal lined slurry pump factories】

Read MoreSlurry Pump Speed

high quality metal lined slurry pump factories...

high quality metal lined slurry pump factories 【high quality metal lined slurry pump factories】

Read MoreHow does a dredge pump work?

high quality metal lined slurry pump factories...

high quality metal lined slurry pump factories 【high quality metal lined slurry pump factories】

Read MoreSeries of TL >FGD pump is a single stage single suction horizontal centrifugal pump. It is mainly used as the circulation pump for absorbent tower in FGD applications. It has such features: wide range flowing capacity, high efficiency, high saving power. This series of pump is matched by tight structure X bracket which can save much space. Meanwhile our company develops many kinds of material targeted on the pumps for FGD.

high quality metal lined slurry pump factories...

high quality metal lined slurry pump factories 【high quality metal lined slurry pump factories】

Read MoreReduced inventory

high quality metal lined slurry pump factories...

high quality metal lined slurry pump factories 【high quality metal lined slurry pump factories】

Read MoreExpertise and experience

high quality metal lined slurry pump factories...

high quality metal lined slurry pump factories 【high quality metal lined slurry pump factories】

Read MoreThe main objective of all flush water programmes is to prevent contamination of the seals by pumped water.The flush water programme for boxes is therefore very similar to the flush water programme for mechanically sealed boxes. However there are still some obvious mechanical differences. The most notable difference is the addition of a seal (packing) between the inlet and outlet limits. This minimises the amount of flushing fluid consumed.

high quality metal lined slurry pump factories...

high quality metal lined slurry pump factories 【high quality metal lined slurry pump factories】

Read MoreTwo types of slurry are found in these industries.

high quality metal lined slurry pump factories...

high quality metal lined slurry pump factories 【high quality metal lined slurry pump factories】

Read MoreThe length of the piping. The longer the pipe, the more slurry-induced friction the pump needs to overcome.

high quality metal lined slurry pump factories...

high quality metal lined slurry pump factories 【high quality metal lined slurry pump factories】

Read MoreA clear clean fluid supplied from an external source is normally used which is delivered to the main sealing surface on the fluid side of the sealing process. By using a closed gap throat bushing, the stuffing box can be back-pressurised to a higher pressure, ensuring that the flushing fluid does not flash across the seal face.

high quality metal lined slurry pump factories...

high quality metal lined slurry pump factories 【high quality metal lined slurry pump factories】

Read More

Popular articles

- How to choose a slurry pump?

- Selecting a dredge pump

- There are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

- - Keeping clean catch basins clean from solids

- We use CFD, CAD method for product design and process design based absorbing experience of world leading pump companies. We integrate molding, smelting, casting, heat treatment, machining and chemical analysis, and have professional engineering and technical personnel.

- Choosing the right pump for your slurry is critical to getting the most out of it. Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear caused by abrasive slurries. Compared to low-viscosity liquid pumps, target=_blank title=Slurry Pump>slurry pumps are typically larger and often require more horsepower to operate because they are less efficient. Bearings and shafts must also be more robust and durable.

Latest articles

-

We know that the right rubber and ceramic liners work very well. They also last longer and can withstand more demanding use. They can also be replaced, thereby extending the life of the pump while reducing operating costs. You can also customise your pump with a variety of ceramic parts, including bushings, pump housings, impellers, wet ends and even seals.

-

The type of application will determine whether a dry or submersible pump solution should be installed; in some cases, a solution that combines a dry and submersible pump may be the best choice. This article outlines the benefits of , submersible slurry pump, versus dry mount pumping and shares some general rules that apply to both applications.xa0Next, the , slurry pump manufacturer, xa0 will share the following content with you.

-

Types of damage to slurry pumps

-

Metal and/or rubber pump bushings are used to combat the erosion of solid particles found in the slurry. Metal slurry pump housings are usually made of carbide to resist erosion caused by increased pressure and circulation. Sometimes wear-resistant steel is used on the pump casing so that the pump can be welded if repairs are needed.

-

Sites often rely on centrifugal pumps to provide slurry service. These pumps (and their associated piping systems) require special provisions that demand detailed knowledge of the properties of solids and slurries to prevent wear, corrosion, erosion and other adverse effects such as solids settling. Specifying the optimum combination of speed, geometry and material requires a proper balance of often conflicting pump priorities; this requires consideration of stable operation, maximum wear life, operational flexibility and minimum energy consumption.

-

Positive displacement slurry pumps with limited capacity to deliver high head are used to pump slurry through pipes with very high solids concentrations.

Links

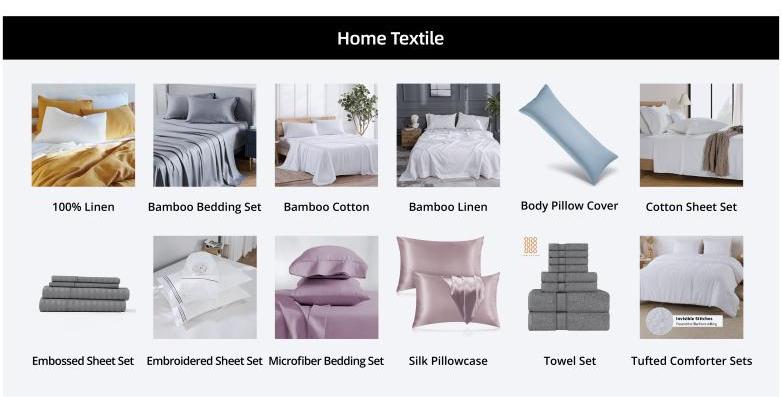

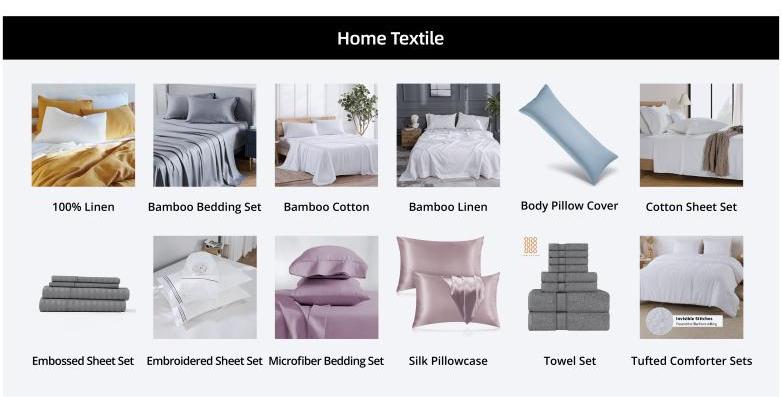

- * Eco-Friendly By choosing bamboo sheets, you're making a conscious decision to support sustainable forestry practices and reduce your carbon footprint.

And if you are concerned with style, one thing to keep in mind is that once fitted to a pillow or a mattress, sateen and percale cotton bedding keep its shape much better, resulting in a cleaner wrinkle-free look.

Ply refers to the number of fibers used to create one thread. One-ply sheets have one fiber, while two-ply sheets have two fibers wrapped together to create a single thread.

Dobby weaves are produced on a dobby loom and contain small geometric or stripe patterns throughout. This weave creates more texture than others, as the shapes (be it squares, diamonds, dots, or the like), have a slightly raised feel. The most common design for bed sheets is thick stripes.

Thread count, ply, weave — what do any of these things even mean? We know you want your bedroom to be a comfortable and warm space to relax and wind down for the day. But with so many types of bed sheets to choose from (and all the jargon thrown around in the industry), it’s easy to give up and purchase a shabby pair that could work okay.

Sustainability

Anatomy of a Bed Glossary

High-quality satin sheets should withstand regular washing without losing their shine or developing pills High-quality satin sheets should withstand regular washing without losing their shine or developing pills

High-quality satin sheets should withstand regular washing without losing their shine or developing pills High-quality satin sheets should withstand regular washing without losing their shine or developing pills best quality satin sheets. It's advisable to look for sheets with reinforced edges to prevent unraveling over time. Additionally, colorfastness is important; the colors should retain their vibrancy even after multiple washes.

best quality satin sheets. It's advisable to look for sheets with reinforced edges to prevent unraveling over time. Additionally, colorfastness is important; the colors should retain their vibrancy even after multiple washes.Varieties and Styles

The supplier should use high-quality materials and follow strict manufacturing standards to ensure that their products are durable and long-lasting The supplier should use high-quality materials and follow strict manufacturing standards to ensure that their products are durable and long-lasting

The supplier should use high-quality materials and follow strict manufacturing standards to ensure that their products are durable and long-lasting The supplier should use high-quality materials and follow strict manufacturing standards to ensure that their products are durable and long-lasting bedding set supplier. You may want to ask about the supplier's quality control processes and request to see certifications or documentation to verify their claims.

bedding set supplier. You may want to ask about the supplier's quality control processes and request to see certifications or documentation to verify their claims.

Our bed linen guide covers the key things to think about when choosing the right bedding, the best sheets, types of duvet covers and pillowcase style. Consider the feel, fabric, weave, thread count, sizes, styles, accreditations, packaging and how to care for your bed linen.

Blanket

A blanket is a generic term that refers to almost any bed covering thicker than a sheet, including quilts, duvets, and comforters. It can also refer to a more utilitarian woven covering that is sandwiched between a flat sheet and another layer primarily for warmth. A blanket drapes over the sides of the bed. Our Chatham blanket is a versatile favorite.

The greatest grade (and most costly) is 100 percent Egyptian cotton, distinguished by its extra-long staple fibers, resulting in sumptuously soft yet incredibly long-lasting sheets.